LASER DYNAMICS

SPECIALIZING IN LASER MATERIALS PROCESSING APPLICATIONS

TEL: (320) 587-2500

FAX: (320) 587-2501

sales@laserdynamics-usa.com

M-F: 8:00 a.m. – 4:30 p.m.

United States, CST

BLACK MARKING

Black Marking is a new laser marking technology that can eliminate the need for the passivation of stainless-steel medical parts after laser marking has been performed. Black Marked stainless parts can withstand hundreds of autoclave cycles without signs of corrosion. Additionally, the marking appears darker than traditional laser marking methods.

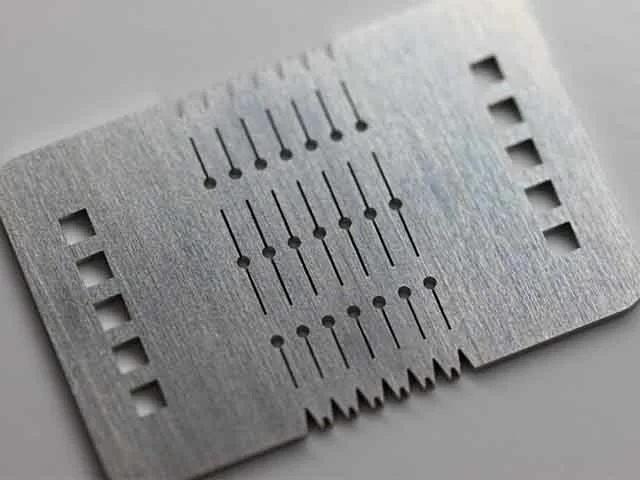

LASER MICROMACHINING

Many industries today are experiencing a revolution in the miniaturization of their components. Laser micromachining is oftentimes the best solution to cutting delicate parts and creating complicated designs. Our processes are non-contact, allowing us to manufacture large volumes of parts identically without the tool wear that is experienced with traditional machining.

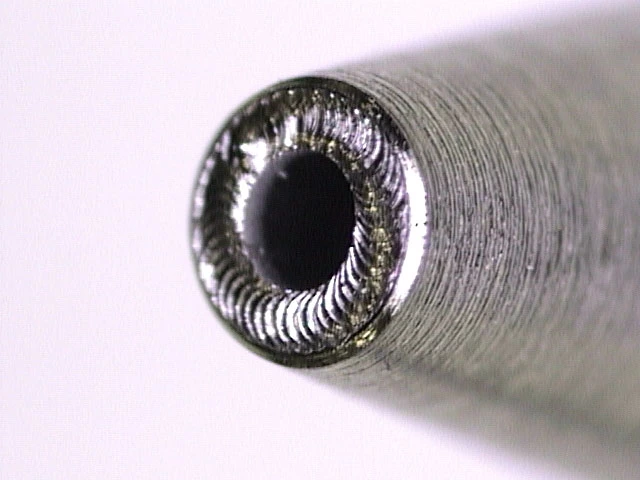

LASER MICRO WELDING

Finding a solution for welding miniature parts can be challenging not only because of the size of the parts, but also because of heat transfer issues to adjacent components. Our pulsed laser micro welding process precisely targets the desired weld area, which puts much less heat into the part than traditional welding processes.

Fiber Laser Cutting

Traditional laser cutting processes and systems have often been dirty processes performed in less than clean environments. Here at Laser Dynamics, we have developed an advanced custom fiber laser system for cutting and drilling small to medium sized stainless medical parts in a clean, medical grade environment.

LASER MARKING

Many businesses require identification on their products that won’t fade or come off during usage. We have developed laser processes that ensure that the identification of your product persists throughout the product’s lifespan. Our goal is that your company’s product is not only identifiable but looks great for years.

GET A QUOTE

GET CONNECTED

Laser Dynamics is capable of shipping parts to anywhere in the United States.

Please consider getting a quote from us for all of your laser materials processing needs, regardless of your locale.

Laser Dynamics does not accept one-time, single part or personalized orders. We perform production runs only.

Laser Dynamics offers free sample testing for all new projects!

Customer Testimonials

See what people in the industry are saying about Laser Dynamics!

Sam L.

(FLORIDA COMPANY)

“Each of you…has been instrumental in shepherding the release and market launch of our new [product]…the first surgery has been completed with great success and a positive outcome for the patient. On behalf of myself, our Senior Leadership Team, other [company] employees, and our medical professional partners and their patients … Thank you, and Congratulations. You didn’t just help us build a product (which you did), but you are directly helping improve the quality of people’s lives!”

Bobbie G.

(WISCONSIN COMPANY)

“The part looks beautiful…Thank you and thank your team for jumping on this so quick[ly]. This shows us what kind of supplier you will be moving forward and we are impressed with how good the weld looks in the pictures…can’t wait to see the samples.”

Angela H.

(MINNESOTA COMPANY)

“Wow! You did a great job with these parts. Thank you for turning around so quickly. I think [company] will be thrilled when they see these.”

Michelle R.

(CALIFORNIA COMPANY)

“You weren’t kidding, your turn around time is great! I wish all lead times were like this.”

Adam S.

(MINNESOTA COMPANY)

“…Your price and lead time have always been very good so you are probably the only place I know of right now that I would be comfortable outsourcing this machining to.”

Michael G.

(MINNESOTA COMPANY)

“We are always pleased with your work and attention to detail.”

John S.

(WISCONSIN COMPANY)

“You continue to establish and maintain one of the finest and well-documented ISO systems that I [have] come across. I would venture to say that it is the best as far as written documentation, organization, and creativity.”

Cameron M.

(MASSACHUSETTS COMPANY)

“I received the samples last week and I’m thrilled with how they came out. The darker gray marking looks great and is exactly what I was hoping for. The scaling of the logo on the smaller and larger [part] is also excellent.”

Terry H.

(WISCONSIN COMPANY)

“You guys are doing a fantastic job!”

Carol R.

(MINNESOTA COMPANY)

“Wow you guys rock – it can all come together tomorrow!! Many thanks.”

Eric B.

(MISSOURI COMPANY)

“Your parts and lead time were great. We are finalizing this project in the field, and we will be placing another order in the next few weeks to supplement production.”

Marcia L.

(ARIZONA COMPANY)

“…I received the [products] and they look great. Thank you for fitting us in sooner than you expected. I really appreciate all you’ve done to get this done.”

Jodi T.

(MINNESOTA COMPANY)

“You guys are the BEST!!”

Jon W.

(MINNESOTA COMPANY)

“Thank you for dropping [the parts] off last night. Was a big surprise to see them on the dock before I left last night. Thank you and your team for the quick turnaround of orders this week! Very much appreicated!”

NEWS

Stay up to date on our latest news, trends and applications as a laser processing company!

Laser Dynamics is featured in a Manufacturing Marvels® video, which aired on the Fox Business Network:

Laser Dynamics, a professional laser materials processing company, specializes in laser marking, laser micromachining, laser micro welding, and laser cutting. We are proud to announce that we have been showcased in a broadcast of Manufacturing Marvels®. This video...

EXCEEDING CUSTOMER EXPECTATIONS

Recently during a standard review of one of our customer’s purchase orders, we noticed that one of the lot numbers on the order was the same lot number that we marked on the parts for the previous order. We stopped the set-up process and contacted the customer to make...